Compressed Air Automation and Data Acquisition Systems

Compressed air auditors are required to test and analyze the condition, efficiency, and operating requirements of compressed air systems on a daily basis. So, what would happen if the industry’s most experienced and trusted auditors designed an automation system to maximize the efficiency of this broad array of compressors and system configurations? This is the heritage iZ Systems Compressed Air Automation and Data Acquisition System.

Product Features

- Compatible with any brand or type of compressor at any pressure

- Controls centrifugals, dry or lubricated screws, reciprocating, high or low pressures

- Interfaces to and controls any existing compressor control type or vintage

- Eliminates the costs of compressor control upgrades

- Controls multiple system pressures on a single platform

- Manage multiple complex systems with one automation platform

- Compatible with pressure flow controllers or load sharing system management

- Allows flexibility to manage each system in the most efficient manner

- Exclusive Cell Modem remote support by iZ’s compressed air professionals

- Eliminates the need to compromise the facility network for remote access

- Provides Ethernet ports for connection to plant networks

- True PLC based Open Platform Software with full user access to primary code

- Eliminates proprietary cables and software which leads to OEM obsolescence

- Allows the client to be self supporting in the long term

The iZ Compressed Air Automation and Data Acquisition System is based on non-proprietary software which conforms to IEC 61131-3, an open protocol software industry standard. This standard insures the Owner that the software can be supported by any trained systems integrator and that the software will not be obsoleted by future versions of proprietary controls. This industry standard protocol also provides interface capability to virtually any hardware or software which the Owner may currently utilize in his facility. iZ Systems provides the complete software program code as a site license to the Owner so he has access to make future modifications or additions to the system with or without iZ support.

Number and type of compressors to be controlled

Control type and version of each compressor

Location of compressors (number of compressor rooms and distance between)

Type of plant information system, if any

Additional data to be collected from the compressed air system

Any additional plant equipment to be monitored or controlled (chillers, boilers, etc.)

Overview of Main Automation Design Benefits and Sample Screen Shots

Product Features

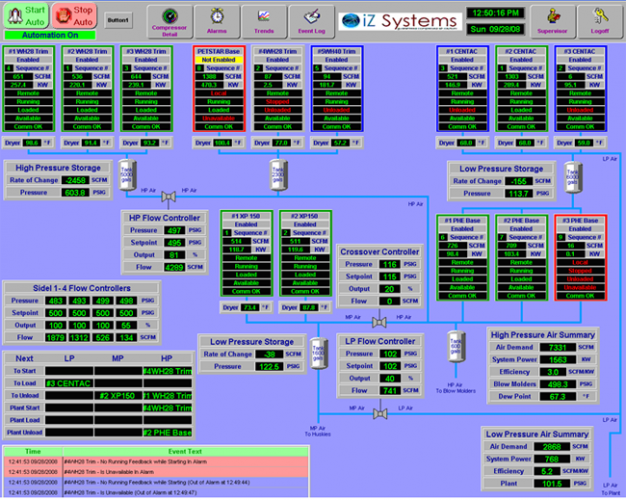

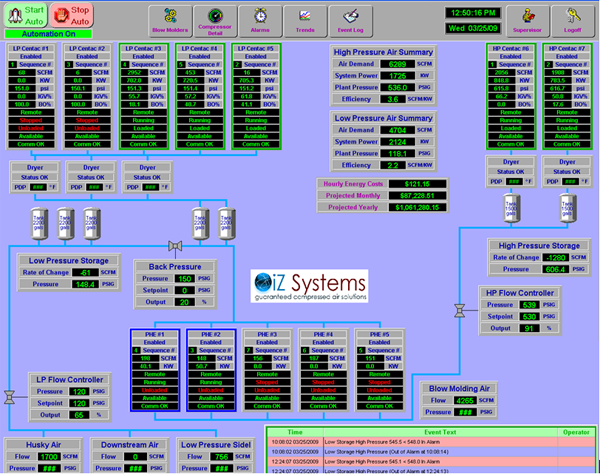

The Overview Screen is a process flow schematic of the supply system storage and header pressures which displays individual compressor status, power and flow to provide a snapshot…read more

The Trending Screen displays a real time or historical graph of all known system parameters including information on system pressures, total power, flow, system efficiency…read more

The Edit Group Screen provides the interface for configuring each pressure system without requiring programming changes in the automation software…read more

The Compressor Diagnostics Screen provides the interface for confirming the status of and testing each compressor in the system. The compressor can be taken into manual mode for testing…read more

The Compressor Setup Screen provides the interface for configuring all compressors in the system without requiring programming changes in the automation software…read more

The Pressure Flow Control Valve Screens (quantity not limited) allow the IZ automation to adjust setpoints and tuning on all control valves in the compressed air systems…read more

The Analog/System Setup Screen provides the location for entering all system parameters which allow the automation to be tuned for the individual needs of each system…read more

Automation Hardware

The standard iZ Compressed Air Automation and Data Acquisition System hardware includes:

Product Features

- A Main Panel that houses the processor, up to 24″ color touch screen, power supply, analog inputs, communication master, and all other related connection hardware.

- An Interface for each compressor includes communications slave, connection hardware, and remote I/O for control and feedback interface to the compressor.

- A Cell Modem Router which allows iZ technicians to monitor and support the system on line without interfacing or impacting the plant’s network. This modem can also be used by plant or corporate personnel to monitor the system remotely.

- Instrumentation as desired to monitor and manage the system including flow, power, pressure, dewpoint, temperatures, etc.

- Optional Remote I/O panel can be provided to collect additional information from the plant that is not available from automation logic or to collect data from other plant facility systems such as boilers, chillers, or cooling towers.

- iZ Automation Brochure Download

Precision Compressed Air Flow Meter

The iZ Systems Precision Flow Meter was designed to our specifications for multiple users and best accuracy.

Product Features

- It sits out of the air stream near the pipe wall to reduce the chance of damage from particulates in the air stream

- Available in various models handling pressures up to 600psig

- These flow meters coupled with kW instrumentation allow our automation systems to track both compressor and system efficiency real time

The iZ Flow Meter is shipped in two pieces, A stainless steel receiver piece is welded into the pipe and contains an alignment guide. As insertion piece with electronics is inserted through the receiver and secured into the pipe so the unit can be pre-calibrated based on the application pressure and precise cross sectional area of the pipe. This eliminates concerns for proper orientation, straight runs, and on site tuning.